Hello, I’m Steve Duckworth, a retired structural engineer and project manager with a lifelong passion for flying and, for the past 30 years, ship modelling.

I’ve spent my life making things. Over the years, I built a car, an aeroplane and a house, you can see pictures of them on my Flickr site. I also held a pilot’s license for 40 years but no longer fly, arthritis caught up with me in the end.

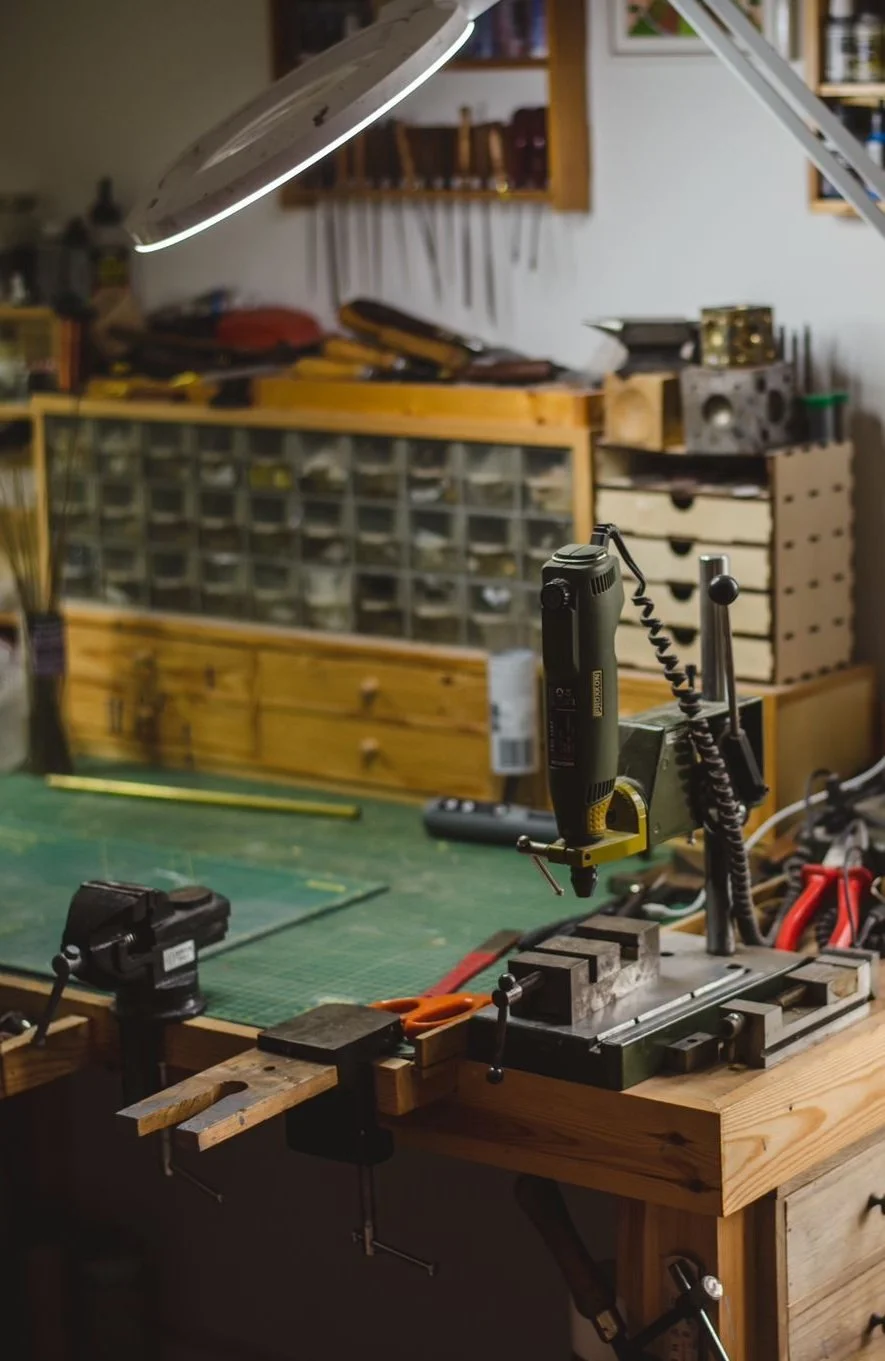

But my first love is ship models, particularly the builder’s models of the early 20th century. I don’t remember where the love of ship modelling came from, my maternal grandfather was a ship’s engineer and a HO ERA during WW1, so it probably started there. My paternal grandfather was a watchmaker and my best tools come from his workshop.

I don’t get on with knots, so you will not find any sailing vessels here. While I’ve tried a few scales, my scale of choice is God’s own scale of ¼ inch to the foot (I remain unashamedly imperial in my thinking). If it was good enough for ship builders to use to display their wares, who am I to object?

1:48th scale is unique in many ways.

To me, the most important being that it is the smallest scale where you can reproduce rivet detail (also) exactly. The problem is, of course, that ships are rather large things and so 1:48th limits, to a practical extent, the range of vessels that can be accommodated in a workshop and find a home thereafter.

I mean no offence to modellers who make up kits or change them, they produce amazing miniature works of art, but I don’t see the point myself. You are starting with someone else’s mistakes and compromises. In my models, the mistakes and the compromises are all my own. I enjoy technical drawing and also happen to like making hulls. Sanding a hull gives you an insight into the mind of the designer that no amount of staring at drawings can compete with. Where possible, I always try to start with original drawings not model plans (other people’s errors etc).

For materials, I try to stick to the principle, if it was metal, make the model piece from metal, if wood then wood. In the past few years I’ve encompassed 3D printing, really the combination of detail and my increasingly inflexible fingers have persuaded me that if the technology had existed 100 years ago, they would have used it.

I also provide a detailed description of my all builds on Britmodeller.com. If you would like to follow the progress of my current projects, I urge you to join this helpful and friendly community.

So that’s me, now in retirement, a passionate ship modeller and maritime researcher. I hope you will find something of interest here. If you would like any more information on any aspect covered here, please just get in touch and I will be very happy to try to help.

My model of HMS Grey Fox was the winner of Chris Deith Memorial Trophy for Best in Show at 2025 Midlands Model Engineering Exhibition